Applications relying on RF systems—everything from unmanned aerial vehicles (UAVs) to radar systems—have evolved towards lighter, high-performance designs but are frequently constrained by lump-element RF components. Benchmark's new filter product lines were designed to give RF engineers new options to address size, weight, and power (SWaP), temperature tolerance, and integration into designs through the ability to stack, embed effectively, and surface mount components.

Benchmark Lark Technology leveraged our 30 years of experience in the RF components space to develop a new line of customizable bandpass, bandpass, highpass, and lowpass filters using LCP material for frequencies up to 40 GHz. Essentially, these are traditional stripline filter designs made using a semi-additive circuit fab process with LCP. This filter design allows our engineers to customize small, wideband, and high-performance filters using fine lines and spaces that are not achievable using conventional filter manufacturing techniques. The overall package is planar and extremely thin, ideal for surface mounting or stacking.

Design Options are Expanded When Filters Can be Stacked

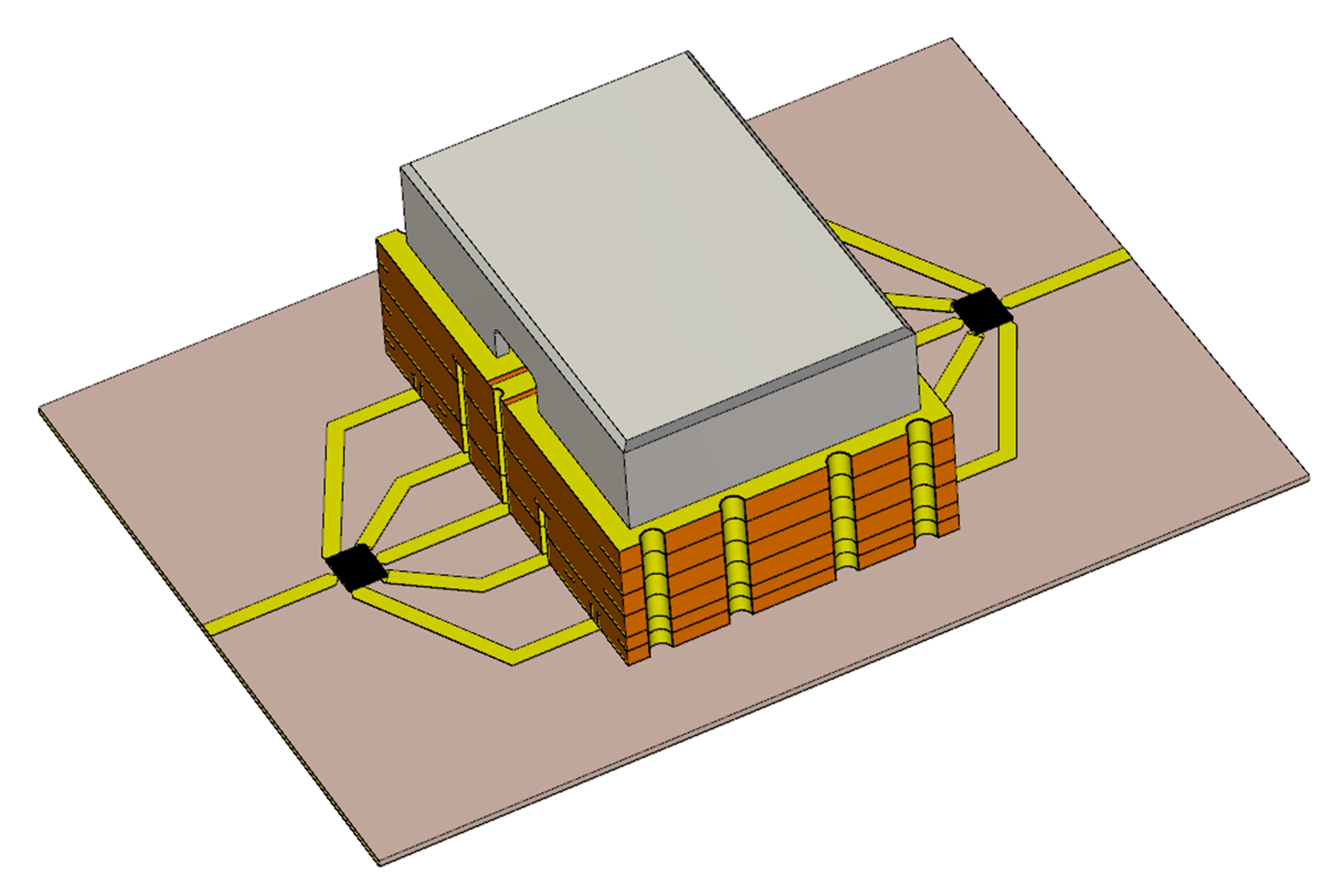

While small filter size is a huge advantage on its own, being able to configure multiple filters in a stack-up further reduces the area required for board layouts in any RF system. It also eliminates the need for interconnects since components are installed using an SMT process. Our customers have been asking for stacked filters as it gives them the ability to integrate more functionality into their RF board layouts. We are also incorporating active functions into a custom surface mountable solution, including switches, mixers, and amplifiers. It is all about the SWaP. Stacking filters gives our customers the ability to significantly reduce size and weight and allows them to get more functionality in a smaller footprint. There is no compromise on performance since these filters still perform comparably to other much larger technologies, i.e., cavity or lumped element filters. This capability can be applied to just about any application requiring filtering, switching, or amplification, including RF front-end, phased array receivers for UAVs, CubeSats, and airborne radars / EW systems.

Switched filter bank showing stacking LCP BP filters

Applications of Smaller, Lighter Filters

The new design possibilities offered by thin, stackable stripline filters, or filter integrated solutions, are starting to impact a number of applications. A few examples include:

UAVs - UAVs are becoming smaller and smaller, so the electronics used for data links, control, and intelligence gathering need to be smaller and lighter as well. Typical sizes are 3 X 5 inches for the entire radio system. Our LCP filters are ideal for these applications due to their small footprint and lightweight.

Airborne Radar/Electronic Warfare – Customers are constantly fighting SWaP due to increased power requirements for systems contained in an external pod. Our small form factor filters allow them to get multiple receiver channels in a typical 3U (4X6 inch) chassis, allowing them to gather even more data in the same footprint. More data means more signals collected for intelligence analysis, more data for signal jamming, and more dynamic range on radar front-end receivers. Due to the inherent accuracy of our circuit fab process, our LCP filters also have a tightly matched phase and amplitude response that is critical for most radar systems.

Satellites (CubeSats and others)—anything that goes into space—need to be radiation-tolerant, which LCP is, and lightweight since any added mass requires more power to keep the satellite in orbit in addition to the power for all the electronics that support its functioning. The greater the mass, the greater the power required and, therefore, the greater the number of solar panels. This drives the overall size of the payload and launch vehicle. Our LCP filters will reduce the mass and significantly miniaturize the size of the radio package allowing for redundancy on a smaller payload size that can be carried by smaller, easier-to-launch satellites.

Filters are Only Part of the Story

Beyond the very small filters themselves, the same materials and circuit fabrication technology that allowed us to build the LCP stripline filters solve RF circuit design problems. The ability to create fine lines and spaces in upwards of 10 layers in a low-loss, low-dissipation factor material such as LCP offers new circuit densification options. Also, the circuit fabrication process and material set are optimal for embedding RF components within a board stack up, an excellent solution for many SWaP challenges across applications. One great example of this technology in action is embedded RF components in 5G wireless infrastructure, such as antenna arrays and switches. In the most advanced RF designs, RF system engineers are opting to mix materials to combine RF and compute functions without interference. This can reduce latency and potential points of failure by eliminating connection points. Engineers in defense and aerospace applications with no tolerance for latency and high-reliability requirements are pioneering this technology, which offers significant potential benefits in many RF applications.

Ready to find how your RF system can benefit from smaller components? Contact us!