2023 marks the 53rd year of celebrating Earth Day, although the annual observance didn’t become a global affair until 1990. “Today, Earth Day is widely recognized as the largest secular observance in the world, marked by more than a billion people every year as a day of action to change human behavior and create global, national, and local policy changes.”1 We are also witnessing a greater number of companies across industries not only supporting Earth Day but developing, maintaining, and growing sustainability practices. This is certainly true of original electronics manufacturing (OEM) companies wishing to reduce their industrial carbon footprint. What is critical to an OEM’s success, however, is finding a trusted and capable engineering and manufacturing services partner with these same values.

Meeting Sustainability Goals

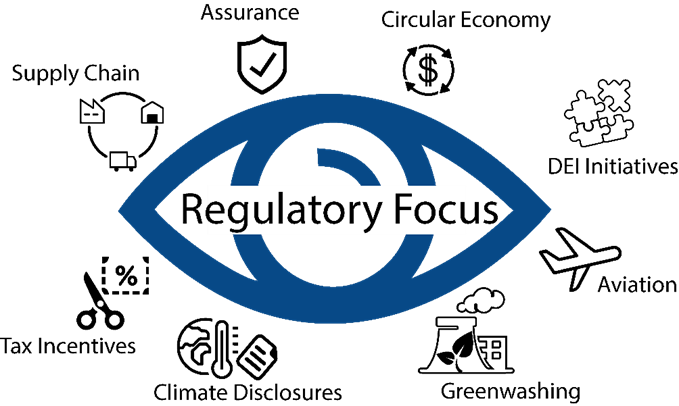

*ESG-focused regulations and incentives are now felt around the world as governments strive to increase corporate social accountability and climate-related risk management, while reducing overall greenhouse gas (GHG) emissions to fight climate change. According to BDO Alliance USA (the United States member firm of BDO International, a global accounting network), regulators are focused on nine key areas, including:

Source: BDO Alliance USA

*ESG: Environmental, Social, and Governance

But mounting regulatory pressure isn’t the only concern facing OEMs. Increasing customer demands and growing investor expectations centering on sustainability solutions are spurring OEMs to reduce their carbon footprint and lower their GHG emissions. Some effective ways to meet these goals include implementing sustainable shipping operations, investing in closed-loop manufacturing processes, reducing waste and water usage, adjusting energy loads, and partnering with the right suppliers and vendors. For these very reasons, sustainability is quickly becoming a powerful market driver.

Sustainability as a Market Driver

According to Bloomberg, “ESG assets will hit $50 trillion by 2025, representing more than a third of the projected $140.5 trillion in total global assets under management.”2 Sustainability is driving innovation forward and creating novel competition to succeed in realizing a low-carbon economy.

“ESG assets will hit $50 trillion by 2025, representing more than a third of the projected $140.5 trillion in total global assets under management.”

From aerospace and defense, advanced computing, and semiconductor capital equipment to medical technologies, next-generation communications, and more, organizations are striving to create sustainable value for their stakeholders, the environment, and their surrounding communities. One sector, in particular, that is focused squarely on sustainability is complex industrials, and advanced technology is leading the way.

Key Technologies Driving Sustainability

According to McKinsey & Company, “industry consumes more energy than any other sector.”3 Industrial companies are, therefore, under intense pressure to develop, implement, and continuously improve its sustainability initiatives. Innovative technologies offer several opportunities for companies to strengthen their sustainability efforts and minimize their carbon footprint. Although several technologies are emerging, the following are the top three technologies we see as the most powerful sustainability drivers:

- Robotics, artificial intelligence (AI), and automation enhance manufacturing and engineering efficiencies in many ways. For one, these technologies reduce the frequency (and severity) of operational errors, resulting in less waste and increased cost savings. Remotely operated vehicles, robotic tools, and automated machines can also seamlessly manage tedious, repetitive tasks while strengthening workforce safety. With built-in specialty sensors, machine automation increases precision and decreases production time.

- The electrification of buildings and machinery allows companies to replace fossil fuels with electric power, lowering their greenhouse gas (GHG) emissions. By investing in EV-ready power distribution systems, electric vehicles, onsite renewables, and efficient energy storage solutions, companies set themselves on a successful path to reaching a low-carbon future.

- Connectivity and digitization improve access to data, drive operational efficiency and predictability, and strengthen workplace safety. Some companies are even pushing forward with digital sustainability efforts to create a circular economy. By leveraging information, operational, and engineering technologies, these companies are able to reuse, repair, refurbish, and recycle products and materials. Investing in a circular economy saves companies—and their customers—considerable costs while greatly reducing unnecessary and harmful waste.

But OEMs don’t have to manage this alone. In fact, many OEMs are now partnering with experienced EMS companies that offer engineering and manufacturing expertise, cutting-edge technologies, and a commitment to transparency through regularly reporting on sustainability and ESG initiatives.

Realizing a Greener Future Together

As expectations increase regarding sustainable designs and clean manufacturing practices, OEMs are actively searching for an engineering and manufacturing partner with a proven track record in environmentally responsible practices, fair and transparent operations, established principles of workplace safety, and more. Benchmark is that partner.

Benchmark offers 40+ years of engineering and manufacturing experience supporting OEMs across industries. We have a longstanding commitment to helping our customers design, engineer, and build products that reduce our collective carbon footprint. Part of this commitment involves ongoing support for customers whose products focus on realizing a cleaner future for everyone.

Electrification in Construction

In an effort to meet their carbon-reduction targets in the near future, one of our customers is actively investing in the design and manufacture of digitized, automated, and electrified heavy machinery. Leveraging an already established, longstanding business relationship with us, our customer reached out to Benchmark to support their efforts. We are honored to provide our expertise in design for excellence (DFX)—including design for manufacturing (DFM) and design for test—to help build the control boxes and printed circuit board assemblies (PCBAs) for their loaders, representing some of the most widely used pieces of equipment within the construction industry. New Product Introduction (NPI) and production ramping of control boxes will also begin in the near future.

Eco-friendly Alternatives for HVAC

The Heating, Ventilation, and Air Conditioning (HVAC) business is also moving toward a greener future and Benchmark is proud to support these initiatives. One partnership, in particular, involves a Benchmark customer specializing in heat pumps to replace oil and gas furnaces. Heat pumps provide a more efficient, less expensive, and greater eco-friendly alternative to oil and gas furnaces, and we are pleased to be a critical part of this greener solution, building the required power boards for their heat pumps.

Sustainable Industrial Practices

When one of our customers approached us to help them design, manufacture, and support the post-production for one of their industrial products, Benchmark rose to the challenge. Our customer’s product uses several microphones to detect air, gas, and vacuum leaks in compressed air systems for their industrial customers. With Benchmark’s support, our customer was able to ruggedize their design, manufacture at scale, and service the product’s post-production needs, including obsolescence management and component/firmware upgrades.

Benchmark—Helping You Meet Your ESG Initiatives

Sustainability matters to our investors, to our customers, and to Benchmark. We invite you to read our 2022 Sustainability Report that showcases our continued ESG achievements and shares our intended targets for diversity, equity, and inclusion (DEI) and GHG emission reduction. By leveraging sustainable engineering practices, our supply chain due diligence, and our operational excellence, your company’s products are sure to drive sustainability forward.

When ESG Matters, turn to Benchmark.