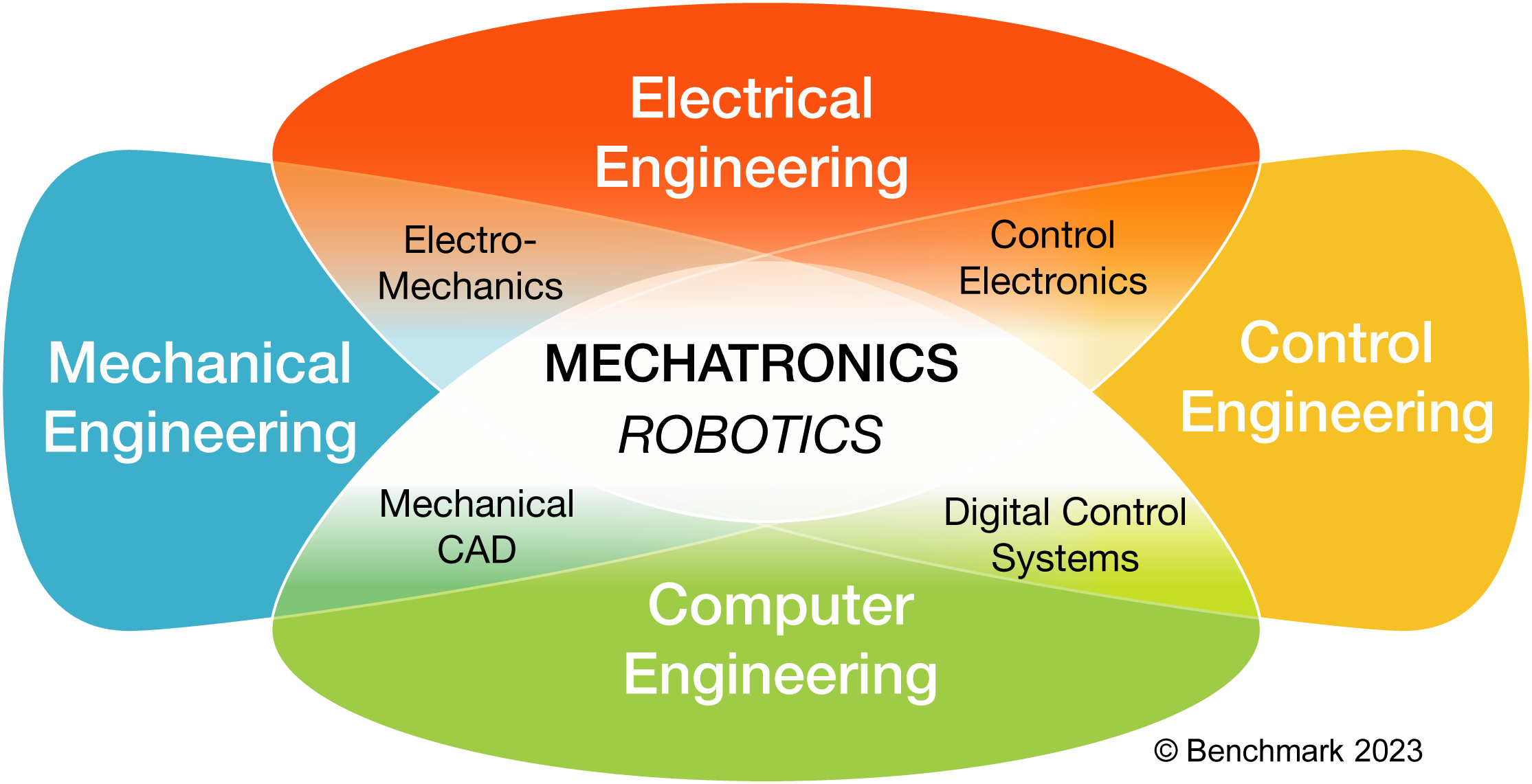

The field of mechatronics has become integral across all industries, from industrial automation and the medical industry to the gaming industry, satellite communication and more. As a multi-faceted and interdisciplinary branch of engineering, mechatronics combines mechanical, electrical, computer, and control systems. Robotics—a subset of mechatronics—incorporates an element of autonomous control to a mechatronic system. The Venn diagram below clearly demonstrates how each of these disciplines interconnect.

There are several advantages to implementing mechatronics and robotics into your design strategy. And, finding an engineering and manufacturing services partner with product development experience and capabilities in each of these disciplines can oftentimes make all the difference.

How Do Robotics Companies Find the Best engineering and manufacturing Partner?

Robotics companies are strongly encouraged to perform due diligence when evaluating partners. Consider only those with proven electronic, mechanical, information, and control systems expertise (and direct experience within your industry wouldn’t hurt either). It is also important to ask if the partner has invested in advanced manufacturing technologies and if they can demonstrate their added value to your product no matter where you are in the design and/or manufacturing process. For example, do they have the engineering expertise to provide input into your design and can they enhance the overall product with design for excellence (DFX) services? However, to truly gain an edge against the competition, find a partner with proven processes and process execution.

Product Realization

Typically, Benchmark engages in customers’ engineering projects that ultimately lead to manufacturing. This is truly the lion’s share of what we do as a global operation. However, it is important to understand that we can—and do—support customers no matter where you are in your design, production, or post-production process. In other words, engagement for us involves any of our support functions for our customers. From day one, our teams ask the necessary questions to intimately learn about your unique needs, allowing us to provide the custom solution, implement the appropriate process, and execute on your behalf. In short, we partner with our customers, leveraging our unparalleled skills to provide value to you.

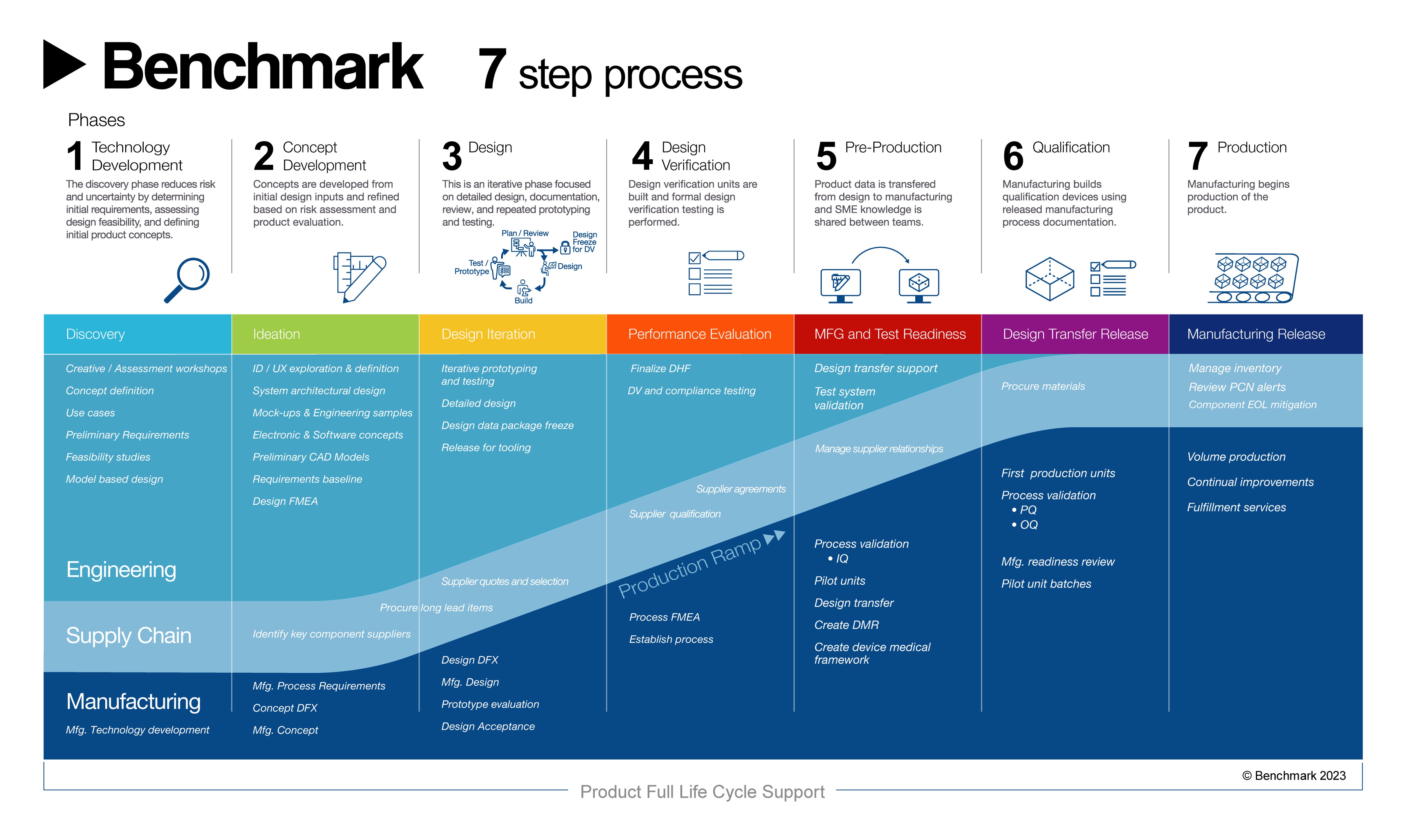

Benchmark’s product realization is a seven-step phase-gate process that enables successful execution of our customers’ products. Since customers can engage with us at any phase, some projects begin with engineering engagement while others begin later on in the process, closer to manufacturing. However, no matter which teams are leading your robotics and mechatronics projects, our program teams will always step up to provide the necessary support such as test development, DFX, design for manufacturing (DFM), manufacturing, engineering, and supply chain management.

Supply Chain Considerations

Supply chain activities are often overlooked during the early phases of product realization which can result in market entry delays and costly changes later in the product maturation cycle. This is best remedied by pulling forward actions and decisions much earlier on in the development of the product. Once a concept is developed—well before you finish designs, drawings, and part lists—you likely still have an idea of the types of parts and components that will make up the product. Therefore, this is the ideal time to develop a sourcing strategy, determine your make/buy approach, purchase long lead-time materials, and even select which suppliers you’d like to invite to bid. Component selection—and even regional sourcing selection—is of particular importance to minimize total landed cost and freight time, and source available alternatives in today’s constrained markets.

Through this exercise, you might realize that you do not currently have a capable supplier for a specific commodity, process, or preferred geographic region. This is the perfect time to find a supplier to increase the likelihood that they are qualified in time to support production. “Should-cost” analysis using specialty software can be performed as soon as 3D CAD files are available. This practice helps guide design engineers in real time regarding which features or materials drive cost on a given part. It also offers suggested changes to reduce manufacturing costs. This specialty tool even provides insight on which geographies might offer the best landed costs. Since there is a significant portion of custom mechanicals involved in robotics, Benchmark customers truly appreciate this additional support, allowing us to run supply chain localization and help with budgetary costing for international markets.

As your project evolves, Benchmark’s teams remain strategically mobilized to evolve along with you. Our product realization process allows you to bring your complex products to market faster, more predictably, and with improved quality.

Partnering with the Best Matters

Benchmark Electronics is home to over 450 engineers worldwide. Our global presence offers the necessary resources, expertise, and partnership to optimize efficiency of your operations and increase profitability. We also bring our partners decades of experience in each of the disciplines that make up mechatronics and robotics, including (but not limited to):

|

|

*Field-Programmable Gate Arrays

*Radio Frequency

Our global footprint allows us to leverage our engineering and manufacturing teams throughout the world to build complex products across industries. Benchmark is your preferred engineering and manufacturing partner, working with you to build the next generation of your product. We customize to your needs. When mechatronics and robotics matter, partner with Benchmark.