Benchmark is a leader in delivering high-quality, turnkey automation and test solutions developed for our customers. Test Solutions are a complete custom manufacturing-ready test solution for the device, sub-assembly, or PCBA. Let's review the many terms employed when discussing electronic circuit board and electronic device testing: inspection, unpowered test, powered test, component test, functional test, acceptance test, bring-up test, design verification test, and validation test. What do they all mean?

Inspection

Inspection is not a test. Inspection is an evaluation of the physical characteristics of a component, sub-assembly, or final product. Optical inspection analyzes characteristics generally consistent with what a human eye could see with optical aids. At Benchmark, most inspection in manufacturing is automated optical inspection and not performed manually. Another form of inspection includes x-ray inspection, which gives the advantage of analyzing physical characteristics not easily viewed by the human eye.

Unpowered Test

As the name implies, unpowered tests are completed without applying an electrical voltage to a circuit – well, sort of. With a bit of irony, the method of unpowered testing is to apply power to a component. Shorts, opens, and impedance measurements are made by applying a low-level controlled current. The test result is calculated using the ever-present V = IR equation.

Unpowered tests are focused on individual or small groups of components. The most popular unpowered test is a test for shorts and opens.

Test developers are careful to minimize energizing circuits of a product during unpowered test execution. It is important to isolate the components being tested during unpowered testing. Accidentally powering a circuit during unpowered testing can initiate unintended effects, which can cause erroneous measurements. Often unpowered tests are classified as “safe to power up tests,” performed as a precursor to full product power up.

Powered Test

Before a powered test, it is always good to apply unpowered testing to check for component or population errors, resulting in product damage or exposing a test operator to a non-safe situation. Once there is assurance that power will not result in unexpected consequences, power is applied to a circuit board or device. Powered testing has multiple variations as defined by the following terms.

Before a powered test, it is always good to apply unpowered testing to check for component or population errors, resulting in product damage or exposing a test operator to a non-safe situation. Once there is assurance that power will not result in unexpected consequences, power is applied to a circuit board or device. Powered testing has multiple variations as defined by the following terms.

Component Test

Continuing with a bottom-up approach, it is helpful to test an individual component or cluster of components. These tests are subtly different from the functional test described next. The focus of the component test is the basic function of the component – not the entire product function. Tests are typically completed through the application of an electrical stimulus, and the component response is monitored. Typical board-level component tests include LEDs, displays, voltage regulators, clock, crystals, etc. Typical circuit clusters tested include voltage dividers, amplifiers, signal conditioning circuits, etc. Component testing could extend to sub-assembly testing. For example, a pneumatic manifold with electric solenoids could be tested as a component. The pneumatic stimulus would be applied, and the result would be monitored. Again, the goal is to test the component functionality. Test implementations could be completed differently from the product functional test as long as it is an adequate test of the component.

Functional Test

A functional test is a test of the intended function of a sub-assembly or final product. Functional test stimulus typically mimics the product environment more closely than component testing.

Product software is often running during functional testing. The product is tested to ensure it properly receives stimulus, processes that stimulus correctly, and then provides the expected response. For example, if the function of a product is to monitor a pulse-ox level, then a simulated (or real) pulse-ox is presented to the product during testing; a functional test would monitor for the expected product response given the presence of a known pulse-ox signal level.

Acceptance Test

A version of functional testing employed during the manufacturing process is the acceptance test. An acceptance test is the last test a product is likely exposed to before being put in a customer box. Often Benchmark completes acceptance testing and packages products for our customer’s customers. The next person to touch the product is the end customer. Acceptance testing must be completed with the utmost care adhering to a formal process to yield high levels of product quality.

A test solution should have a formal specification of each test requirement. The specification is how a test developer knows what stimulus to apply, what to expect when a test executes, and it gives a basis to know a test has been completed correctly or not.

A test solution should have a formal specification of each test requirement. The specification is how a test developer knows what stimulus to apply, what to expect when a test executes, and it gives a basis to know a test has been completed correctly or not.

The test specification is essential for acceptance testing. Having completed confirmation of each test per the approved validation protocol, Benchmark meets a contractual agreement that the product shipped meets the customer expectations – the expectation detailed in the test requirement specification and validated by the test development process.

At the acceptance test, every part of a circuit or product is not tested. Component-level testing is not always achievable due to a lack of access. Reliance is on the process tools and aforementioned test steps as part of the entire inspection and test process. For example, noise filters are generally not tested with electrical noise but inspected and tested as components. This approach forces a reliance on manufacturing processes. If noise filters are not tested as part of the acceptance test, then another inspection and component testing are paramount.

Design Verification Test

A term used during product design and tester design is Design Verification. Design verification isn’t a specific step during the design process; it is testing performed progressively during the tester design process.

Design verification is not itself a type of manufacturing test solution. Rather, it is a process to qualify a manufacturing test solution.

The purpose of test solution design verification testing is to verify that all system components (custom or off the shelf), interfaces, subsystems, and software tools were assembled and worked as intended. Verification that the design employs good practices and works as expected is the goal.

Often test strategies proven during product design verification testing are leveraged during the development of manufacturing test solutions. Reuse of the knowledge of the product during design verification testing can give a manufacturing test developer a head start for test solution development. However, a common approach is to slide design verification test solutions into the production environment. The operation of these test solutions is often rudimentary, requiring an engineer or technician level knowledge to complete. This is problematic in the manufacturing environment. Not only may the test operator be a higher cost resource, but a design verification test solution is likely not manufacturing ready, not robust, and may not identify test faults adequately. Poorly identified defects add further to the cost of the test debug loop as manufacturing resources struggle to repair the failing product. Transitioning design verification solutions into manufacturing processes should be avoided.

Often test strategies proven during product design verification testing are leveraged during the development of manufacturing test solutions. Reuse of the knowledge of the product during design verification testing can give a manufacturing test developer a head start for test solution development. However, a common approach is to slide design verification test solutions into the production environment. The operation of these test solutions is often rudimentary, requiring an engineer or technician level knowledge to complete. This is problematic in the manufacturing environment. Not only may the test operator be a higher cost resource, but a design verification test solution is likely not manufacturing ready, not robust, and may not identify test faults adequately. Poorly identified defects add further to the cost of the test debug loop as manufacturing resources struggle to repair the failing product. Transitioning design verification solutions into manufacturing processes should be avoided.

Validation Test

Another test term used during both the product design cycle and the test solution design cycle is validation testing. Relevant to product design, validation testing focuses on the product's success to meet the intended product end-user requirements. Validation of a test solution focuses on the ability of the test solution to test for the product acceptance criteria repeatedly. The criteria are specified in the test requirements specification and are likely a subset of the original product end-user requirements. For example, the test solution will be validated to correctly detect the functionality of a product display to sense a finger touch. Validating the finger touch triggers the correct user interface is product validation.

Product and test validation focus least on low-level components and most on verifying end product or test solution design requirements. Validation testing is completed in the end environment by end customers. Product validation is completed by end-users (usually under the guise of a clinical review). Test solution validation is completed in the manufacturing environment where the tester is intended to be used. Simulation of the end conditions is allowed with minimal deviation.

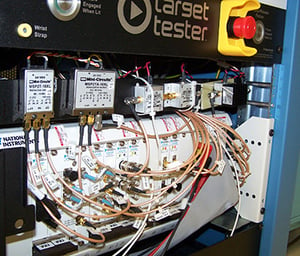

No matter how complex or for which purpose a test solution is required, Benchmark has the engineering expertise to start with a vision of the test need and drive the test design to completion. The test design process includes the requisite planning, design reviews, documentation, etc., expected of a mature design firm.

Manufacturing test processes improve quality among 5G, ruggedization for Aerospace and Defense, and Internet of Things (IoT). Next, I'll be tackling Testlink, what it is and why you need it, and test data storage for medical devices. Stay tuned for these and more topics relating to your test road map for a successful product launch.

Learn more about Benchmark's Automation & Test Design.