The axiom goes, "Use the right tool for the job." However, when it comes to establishing an effective, high performing supply chain, there is often far too much ambiguity and/or complexity to select the "right tool." We often don't know or haven’t identified  which variables we will encounter along the way during product development, scaling up production, or anticipating market demand. I would argue that it is more important to design an effective supply chain utilizing a set of rules-based logic that is flexible enough to work with the variables we know we will encounter along the way. After all, the key to success when dealing with variables is to properly identify and manage them consistently.

which variables we will encounter along the way during product development, scaling up production, or anticipating market demand. I would argue that it is more important to design an effective supply chain utilizing a set of rules-based logic that is flexible enough to work with the variables we know we will encounter along the way. After all, the key to success when dealing with variables is to properly identify and manage them consistently.

Now, if a supply chain is to be subjected to a set of rules, one must first determine what the critical drivers are that will determine the rules. For example, if the product is likely to have very low demand, such as a commercial airliner or a fighter jet, which are only produced in the dozens or hundreds of units per year, then the demand itself is a critical driver of the rules around that supply chain. In this example, the demand necessitates certain rules be generated around this assumption. For the sake of supply chain continuity, we need to make sure that it has sufficient capacity and capability to meet and indeed, surpass the scale requisite to meet the demand.

You may note that quality  has been left out of the considerations, as we should be able to assume that quality is an order qualifier, not an order winner. Though, it is still important to scrutinize the quality requirements of the program and the quality capabilities and expectations of the supply chain to meet those requirements throughout the lifecycle phases of the product. Nevertheless, in world-class supply chains, quality is table stakes as the saying goes.

has been left out of the considerations, as we should be able to assume that quality is an order qualifier, not an order winner. Though, it is still important to scrutinize the quality requirements of the program and the quality capabilities and expectations of the supply chain to meet those requirements throughout the lifecycle phases of the product. Nevertheless, in world-class supply chains, quality is table stakes as the saying goes.

Starting Point

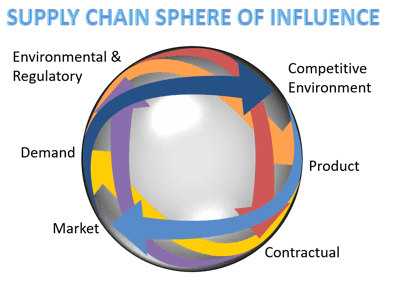

So how does one go about identifying all of the variables one must take into consideration when architecting a world-class supply chain? This article presents the primary elements, along with some subsets of the elements, which require a level of scrutiny in order to establish an effective, high performing supply chain.

The supply chain must take into account each of the elements within the sphere of influence which may have a major impact on the supply chain design. Rules can and should be developed to ensure a consistent outcome and application against each of those elements to which it is to be subjected. The rules are generated around specific variables.

Variables Require Rules

Those variables usually include

some of the items outlined below:

- Competitive Environment

What provides a competitive advantage; price, availability, service, image, reliability, simplicity? How proprietary is your product? How faithful is the customer base? How sensitive is the product to pricing considerations? - Market Considerations

-

-

Market Focus - Made in the U.S., EU, or China? Is there a requirement based on customer needs or expectations? Is your customer expecting top of the line or the cheapest of the cheap? Understanding market expectations is a critical factor in designing the supply chain for optimal performance throughout the lifecycle of your product.

-

-

-

Market Location - Which geography is the customer in? How critical is it that the supply is co-located with the market? What geopolitical or taxation considerations need to be included in the supply chain design? Some markets require in-country sourcing and manufacturing in order to participate in that market. Others have little or no trade restrictions or barriers. Some customers care about where the product is made. Cost plays a significant role in the design of the supply chain and consequently, choosing where the product is made becomes a critical part of the equation as well.

-

-

-

Industry and Segment - Industrial, Medical, Next-Gen Communications, Aerospace, Advanced Computing, Semi-Cap, Energy, or Defense. Each one has nuances that need to be taken into consideration when designing the supply chain. Reliability also enters heavily into the equation as we consider industry and segment standards or competitive advantages.

-

-

Product Considerations

-

Product Design - Mechanical products typically have a fairly straightforward supply chain. Electronics can have a decidedly more complex supply chain associated with it. When you bring the two worlds together to create mechatronics, the supply chain continues to increase in complexity requiring more thought input to the architecture of the supply chain.

-

Product lifecycle Phase - What phase of the lifecycle is the product in? Development, new product introduction, launch, growth, mature or end of Life? Will aftermarket support be required? Reverse logistics have become increasingly important given the higher value of the product and/or environmental impact?

-

Pricing Strategy - Market segment or customer classification: Regardless of who your customer target is or how you slice and dice your markets, your pricing strategy must be supported by a cost structure that makes the business case feasible. Architecting a scalable supply chain that meets those needs is the most critical step in realizing a successful product launch and keeping it sustainable for the duration of its designed lifecycle.

-

Intellectual Property - Is the IP internally or externally held? What happens if the IP is compromised? What happens if the IP is no longer available? Is the IP sufficiently protected? While IP is often protected from theft by patent law or trade secrets, there are occasions where the IP may not be protected with regards to continuity or availability for the product it is used in, effectively impairing the product or the business.

-

-

Demand Considerations

-

Demand Levels - What volumes will the product have? What is the life span of the product? Apple will have shipped over 1.6 billion iOS devices by the end of 2019 and expects that number to hit 2.0 billion in 2021. Staggering numbers like that require extraordinary supply chain measures to meet demand. Conversely, the B-1 bomber, developed in 1973 and produced until 1988, yielded only 104 units over a fifteen year period and are planned to remain in service until after 2025. Clearly, the supply chain required to produce and maintain a product like that is special and has myriad considerations required to support it over a span of more than fifty years.

-

Demand Patterns - Also a consideration in the design of the supply chain, the pattern of demand is a critical feature that needs to be accounted for properly in order to maintain product availability during cyclical demand and recession periods. Missing a critical launch date can devastate a product’s lifecycle and permanently impair the business. Likewise, not having enough product available for ready sale may cause your customers to buy your competitor’s product instead; guaranteeing you never get that sale. Inventory strategy and optimization become critical outputs of understanding demand patterns.

-

-

Environmental and Regulatory Considerations

-

Environmental Impact - An item produced in low volumes is not likely to have much of an environmental impact after its useful life, but many consumer goods produced in the millions of units can have a massive impact on the environment. Establishing a reverse logistics plan to reclaim those products so that no harm is done to the environment is important. Perhaps even more important than reclamation is how responsible is the entire supply chain in the production of that product? There are compliance laws and ethical considerations that factor into the design of the supply chain.

-

Regulatory Requirements - While food, medical, aerospace and defense products all have high regulatory oversight and strict requirements regarding adulterated supply chains, each has its own requirements which have their own specific associated actions to reduce risk of liability, warranty, expected lifecycle longevity, and supply continuity. As such, the flow down requirements may vary as well as the expectations placed upon the supply chain.

-

-

Contractual Requirements

Firm fixed pricing time periods, warranty requirements, supply continuity clauses, and myriad other concerns and factors need to be taken into consideration when designing the supply chain. Contractual requirements span all of the considerations and bring it all together into what should be a purposefully designed, symbiotic relationship allowing all of the parts to work together to support the business. It is the framework upon which all else is enabled to work together and should be undertaken with all diligence to assure the intentions of the supply chain design are adhered to long after all of the original authors of the design have moved on. Good contracts enshrine the intentions of relationships.

and bring it all together into what should be a purposefully designed, symbiotic relationship allowing all of the parts to work together to support the business. It is the framework upon which all else is enabled to work together and should be undertaken with all diligence to assure the intentions of the supply chain design are adhered to long after all of the original authors of the design have moved on. Good contracts enshrine the intentions of relationships.Given the complex interwoven world of variables, it becomes ever clearer how important establishing rules-based logic is to architecting a high-performing, sustainable, repeatable and optimized supply chain. Customers partnering with Benchmark have access to world class supply chain design and architecture services tailored to their needs in order to take their business to the next level.