Light detection and ranging (lidar) technology is a remote sensing feature most notably used in newer model cars that is also employed to safely guide robots and autonomous vehicles on manufacturing floors and warehouses. Lidar has been used for over 20 years by the U.S. Department of Agriculture (USDA) to map the effects of agriculture on the environment. Lidar transceivers transmit laser or light pulses and receive their reflections to learn more about a target, just as sonars use sound waves and radars use electromagnetic (EM) pulses in much the same way. Lidar sensors scan in 360 degrees to collect point clouds of data to process into two-dimensional (2D) or three-dimensional (3D) images of an object for such functions as target spotting, geographic mapping, and gas leak detection.

The technology is an attractive tool for many users, whether for military, aerospace, industrial, medical, or automotive electronic systems. Command of the technology is not trivial and often requires specialized engineering design and manufacturing skills, with precision that apply not just to photonics and spectral imaging circuits, but to companion circuit technologies, including RF/microwave and high-speed digital circuits. Fortunately, Benchmark offers the engineering design and manufacturing experience and a proven track record in creating specialized photonic prototypes and small volume lidar circuits as well as cost-effective, high-volume lidar solutions.

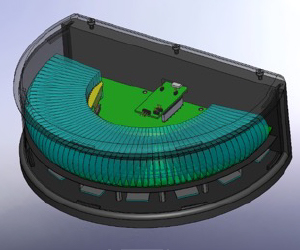

Image: A short-range, low-cost solid state flash lidar subassembly with 64 lenses for each IR PIN photodiode designed by Benchmark. |

To provide comprehensive lidar design and scaled production, Benchmark operates multiple global facilities, duplicating manufacturing capabilities (as well as suppliers) to avoid supply chain issues that have plagued electronics technology suppliers in recent times. The facilities are designed for different volume scales. Our North American Engineering Services team can support design development to help customers develop their designs quickly and transfer to a variety of global sites. For example, the Phoenix, AZ site is geared for small-to-mid-sized production runs, such as that required for military and aerospace customers; the Thailand plant is fully automated for high-volume production and testing, as might be needed by automotive industry standards and requirements. |

Both facilities are supported by experienced staff and the high-precision machine tools needed to create and mass produce lidar designs. Highly automated manufacturing systems include tools for the precise placement and attachment of surface-mount-technology (SMT) components on PCBs, epoxy die-attach, and aluminum and gold wire-bonding systems for reliable and repeatable attachment of microminiature components to meet the most challenging requirements for miniaturization, such as those found in military and aerospace applications. Small size, weight, and power (SWaP) requirements for lidar modules is a key attribute of highly integrated systems on UAVs and other aircraft.

Part of the Whole

System integration with miniaturization is a requirement for most applications for lidar technology, and a broad command of electronic system and circuit design and manufacturing techniques are necessary skill sets. Experience with these applications at multiple Benchmark facilities designing cost-effective lidar into a PCB or subsystem module is one part of a whole. The point cloud data collected by lidar sensors must be digitally processed, requiring capable high-speed digital circuitry and RF/microwave circuitry enabling the communications channels that transfer lidar spectral images. Benchmark’s use of advanced circuit simulation software at the design stage helps customers understand how different technologies, such as RF/microwave, high-speed digital, and photonics circuits and devices will behave when closely spaced on a densely packed PCB.

Helping customers develop producible lidar design solutions that meet target performance specifications is part of the overall challenge since they must be manufacturable consistently and at volume to provide fool-proof performance, whether in the smaller volumes of military systems or the high volumes needed for automotive applications. Along with circuit simulation tools at the design stage, design for manufacturability (DFM) and design for assembly (DFA) practices evaluate whether a lidar design’s line spacings, component placements, and other electrical and mechanical parameters can be produced with available automated manufacturing equipment, while still meeting the circuit tolerances needed for high-performance repeatability and excellent manufacturing yields. These software tools combine to reduce the number of design iterations needed to meet design goals and to accelerate the time from a design goal to a final product.

Of course, no lidar system would be finished unless fully tested and compliant to specifications. The Benchmark lidar design and manufacturing teams, together with specialized facilities well equipped with customized measurement systems and test chambers to ensure that a lidar system performs as expected and will not fail in the field. For example, automated micro-optical alignment systems ensure that lidar transmitters, receivers, and transceivers meet specified performance levels while field of view (FOV) testers check for total spectral coverage.

Lidar systems are typically one of the multiple electronic systems in an application, often used in conjunction with other forms of sensors, including thermal imaging sensors and hyperspectral imaging systems. Benchmark’s lidar testing capabilities evaluate a lidar design alone or with its companion subsystems, as might be the case in a UAV application. Working closely with automotive lidar customers, Benchmark developed two Class 10,000 clean rooms and an end-of-the-line (EOL) test room in its Thailand facility for high-volume production lidar testing requirements. The EOL room also enables environmental testing for full range temperature testing and emulating the operating conditions of an application.

Lidar is a useful technology for many applications, helping to make many environments safer, from the battlefield to the highway. It requires advanced engineering and manufacturing capabilities for successful and practical design and production. With specialized design and manufacturing skills and equipment, lidar has been shown to be an invaluable addition to electronic systems. Benchmark can help shed more light on making lidar systems work where they can add the most value to a design.

About Benchmark

From circuits and assemblies to full systems, Benchmark draws on design knowledge and experience in multiple technologies to meet the most challenging high-speed, high-frequency requirements for current and future electronic markets. For markets that include communications, aerospace, and defense, Benchmark applies expertise in high-speed digital, RF/microwave, and photonics design with innovative miniaturization approaches to develop optimum solutions in the smallest sizes possible. From satellites to 5G infrastructure, Benchmark mixes technologies to the best advantage, saving size, weight, and power (SWaP) in high-speed, broadband electronic solutions that meet or exceed the most difficult custom requirements at gigabit and gigahertz rates.