Miniaturization: Why Size Plays a Major Role in Product Design and How We Achieve It

The evolution of the electronic and computing industry has two aspects: size, weight and computing power (speed/frequency). Seventy years ago the first computer was built occupying an area of 1800 sq. ft. and weighing over 27 tons. Today, we carry around computers with much more computing power on a daily basis in the form of cellular devices. While the decrease in size is very apparent, the other concern is speed. Overcrowding at lower frequencies has forced many industries to shift to the millimeter wave spectrum. The military, aerospace, and communications industries have been constantly driving toward high frequency and high speed. However, with high speed comes challenges like signal integrity, parasitics, electromagnetic interference, etc. The medical industry is also shifting toward miniaturization. Smaller form factors will launch a huge improvement in the convenience of medical equipment and increase the quality of human life. Consider the example of a Ventricular Assist Device (VAD) used by patients with a frail heart that need aid in heart-related activities. Today’s VAD is a bulky device, and miniaturizing it in terms of size, weight and power (SWaP) could enable a person to carry a VAD the size of a cellular phone. The impact of SWaP design improvements in electronics will be immense. In this competitive era, if a product is to achieve market success, it is essential for it to be small, lightweight and power efficient.

military, aerospace, and communications industries have been constantly driving toward high frequency and high speed. However, with high speed comes challenges like signal integrity, parasitics, electromagnetic interference, etc. The medical industry is also shifting toward miniaturization. Smaller form factors will launch a huge improvement in the convenience of medical equipment and increase the quality of human life. Consider the example of a Ventricular Assist Device (VAD) used by patients with a frail heart that need aid in heart-related activities. Today’s VAD is a bulky device, and miniaturizing it in terms of size, weight and power (SWaP) could enable a person to carry a VAD the size of a cellular phone. The impact of SWaP design improvements in electronics will be immense. In this competitive era, if a product is to achieve market success, it is essential for it to be small, lightweight and power efficient.

Figure 1: Liquid Crystal polymer - alternative to polyimide

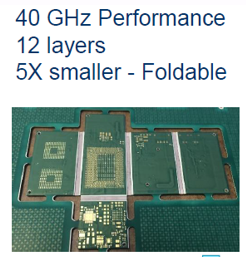

A unique fabrication process is developed using LCP wherein the lines and spaces have the ability to be as low as 1 mil. Interconnects such as bus connections used to connect multiple boards in a system are components which take up a lot of area and also add to the weight. This issue can be solved by designing embedded interconnects using LCP. LCP will also provide much needed flexibility to the interconnects, which affects the size and weight of the system. LCP’s flexibility also enables the circuit to fold and fit into a miniaturized frame.

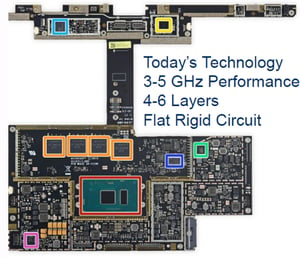

Figure 2: Miniaturization of a Printed Circuit Board using LCP

Technology has come a long way in the last 70 years. From ENIAC, to desktops, laptops, and now by wisely using the properties of advanced technologies, Benchmark has shrunk computers down to compute cubes [See Figure 2 above]. With innovative design guidelines and careful utilization of advanced technologies, Benchmark can bring about next generation miniaturization in the electronics industry, thus advancing the quality of our everyday life.

Connect with us to discuss your next electronics design challenge.