Space captures the imagination, offering new frontiers to explore and endless technological challenges to overcome. Electronics that operate in space are often cutting-edge but also need to be tough; they contend with radiation, extreme temperatures and the stress of moving from the ground through the Earth's atmosphere to the vacuum of space. There’s no Maytag man to make repairs in space. So, once a satellite, rocket or probe has launched even the smallest failure can mean the end of a mission. Balancing the need for bleeding-edge tech and proven reliability is at the core of developing technology for space.

The space industry has always been held hostage by the constraints of mass due to the cost of getting into orbit, but historically volume has been less of a problem since space is, well, spacious. Over the past decade, CubeSats have proliferated as a low-cost, low-risk way to iterate technology in space. With standard sizes of 3U (30cm on each side), 6U (60cm on each side) and 10U (100 cm on each side), these mighty little marvels are driving the miniaturization of components and microelectronic systems for space deployment. Historical costs for satellite development have been enormous for large (1100+ lbs.) geostationary satellites. Technology miniaturization helps to reduce the cost of satellite deployment from assembly to launch.

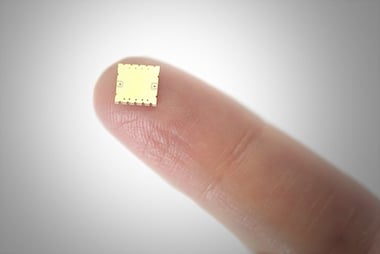

Heterogeneous Integration (HI) is driving the next leap forward in the reduction of the size and weight of most electronic systems.

Reducing the volume of electronics generally leads to packing things into a much tighter volumetric package. This miniaturization can lead to hot spots and thermal management challenges. From the mechanical perspective, we want to make sure temperature-sensitive components are not packed right next to components which have high thermal gradients. In traditional satellite design, the layout was large enough in volume to spread these components out, thus dispersing the heat. Smaller space tech, like CubeSats, presents a new challenge since heat is easily trapped in the layers of the cube. Smaller space systems use strategies like integration of Thermal Interface Material (TIM) to spread heat from the core of the cube to the exterior, or specially designed heat dissipation systems, which turn the faces of the cube into a heat management tool.

Reducing the volume of electronics generally leads to packing things into a much tighter volumetric package. This miniaturization can lead to hot spots and thermal management challenges. From the mechanical perspective, we want to make sure temperature-sensitive components are not packed right next to components which have high thermal gradients. In traditional satellite design, the layout was large enough in volume to spread these components out, thus dispersing the heat. Smaller space tech, like CubeSats, presents a new challenge since heat is easily trapped in the layers of the cube. Smaller space systems use strategies like integration of Thermal Interface Material (TIM) to spread heat from the core of the cube to the exterior, or specially designed heat dissipation systems, which turn the faces of the cube into a heat management tool.

Heterogeneous Integration (HI) is driving the next leap forward in the reduction of the size and weight of most electronic systems. Integrating what was previously several separate systems into one board or chip can greatly reduce the number of components in a satellite, reducing size, weight, and potential points of failure. It also decreases the number of components that need to undergo the certification process, saving time and money.

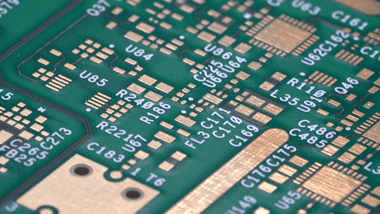

Modification of standard off the shelf components to withstand the rigors of space is becoming a more common practice to reduce development costs. In traditional space technology development, testing and documentation generally cost several multiples more than all the components and parts combined. The production scale of commercially manufactured products lowers testing costs by amortizing costs over larger production volumes. Companies can inexpensively modify dozens of commercial parts for radiation or thermal tolerance, then test and certify them, and finally use those parts in multiple designs.

Combining HI along with commercial components to create integrated hybrid circuits gives space technology companies the best of both worlds. However, development of these designs can be challenging. Close collaboration between circuit design, fabrication and micro-e assembly is required to make everything work together in harmony.

Benchmark partners with all types of space technology companies, from bold new startups to industry mainstays like NASA-JPL, to provide miniaturization solutions for challenging space applications. Our RF/Microwave & Microelectornics Center of Excellence combines circuit design and material expertise with micro-electronics, traditional SMT electronics assembly, and complete testing under one roof for rapid iteration and problem-solving. We design circuits with small lines and spaces allowing space technology leaders to reduce the total number of components in a design. Our micro-e capabilities allow us to embed commercial components, creating significant additional cost advantages.

Benchmark partners with all types of space technology companies, from bold new startups to industry mainstays like NASA-JPL, to provide miniaturization solutions for challenging space applications. Our RF/Microwave & Microelectornics Center of Excellence combines circuit design and material expertise with micro-electronics, traditional SMT electronics assembly, and complete testing under one roof for rapid iteration and problem-solving. We design circuits with small lines and spaces allowing space technology leaders to reduce the total number of components in a design. Our micro-e capabilities allow us to embed commercial components, creating significant additional cost advantages.

Technology constantly changes and new developments are being discovered every day. We love to learn and we are going to keep pushing the limits of technology to help our customers go where no person has gone before!