As the aerospace & defense market has slowed down the entry of new aerospace vehicle development, original equipment manufacturers (OEMs) have had to face the overwhelming task of trying to pack more technology into existing vehicles, under the constraints of the legacy systems.

In addition, there is a growing need to limit any changes in order to keep testing and re-certification costs down. While the costs of development, testing and the overall vehicle system have soared.

Learning from the Past

There have been numerous attempts to minimize the impact of introducing new technology in the development of custom solutions to solve these problems.

Initially, the A&D industry attempted to utilize commercial off-the-shelf (COTS) products but keeping up with the pace of advancing technology drove obsolescence and the relatively limited buying power of A&D compared to the consumer market could not effectively influence the direction of technology development or adoption rates.

A&D attempted to control costs and follow automotive supply chain practices, only to find similar limitations in their ability to influence and adopt technology. While the automotive industry supports COTS practices with its high availability and short operational product life cycles, aerospace vehicles must remain operational for over 30 years.

Even with the market’s high rate of technology demand and heightened advancement in recent capabilities, it pales in comparison to the rate of change in automotive.

What is left is the challenge of trying to provide cost-effective and timely solutions to meet the demands of A&D application advancements in existing vehicles with the added pressure of size, weight, power, cost and thermal management reductions.

The industry had been too focused on attempting product transfer from the consumer market and not how to best adopt the core technology and processes.

A&D engineering talent works hard to be the best in their field and stay at the forefront of what is technically possible for the industry. But trying to stay up to date on applicable technology advancements that enable OEMs to be sustainable and get back on a path of technology breakthroughs may require the utilization of alternative industry methods and not products.

Introducing Innovation

OEMs have turned to boutique firms for research and development, engineering and product design for innovation. These firms’ livelihoods depend on being aware of best of breed technology and understanding how to effectively bring that technology to their clients.

OEMs have turned to boutique firms for research and development, engineering and product design for innovation. These firms’ livelihoods depend on being aware of best of breed technology and understanding how to effectively bring that technology to their clients.

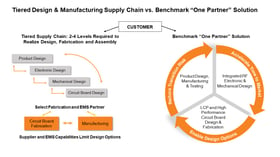

The resultant designs, although good, are often difficult to build, cause delivery delays, quality issues and slow entry to the market. The same issues can occur in the OEM’s own designs, which often have to go through several design modifications in order to be produced.

Boutique engineering teams, while innovative and nimble, cannot scale and struggle to design to specific scaled manufacturing capabilities. This results in complex designs with very tight design tolerances that require multiple redesigns in order to build at 100% delivery and 100% quality, further delaying the time to market and driving up costs.

What this ineffective process is missing is a way to take advantage of breakthroughs in technology across all the markets and optimize these technologies for manufacturability, providing real results for the demands of the of the aerospace market.

The New Age of Change

The age of tight vertical integration and slow, proprietary processes is no longer acceptable given the speed of innovation and the necessity to leverage incredibly broad and dynamic market innovation. The majority of ground breaking innovations are happening in the other markets, such as next-gen communications with 5G and satellites, medical with miniaturization in neutral media and sensor integration, industrial with mesh net tracking and smart cities and semiconductors with sensors, Flash, DRAM, OLED, MEMS and microcontrollers.

Vertical integration for some of the electronics systems of an aircraft may make sense, as it defines the aviation vehicle’s value proposition. But more importantly, for the market to get back on track, OEMs must partner early with suppliers that have multi-market technical integration knowledge with scalable production facilities to bring forth sustainable technology and the production advantage that A&D needs to meet the demands of today’s market.

Traditionally, Electronics Manufacturing Services (EMS) firms have been innovative on the production floor, introducing additive manufacturing and robotics but they have not known how to help the OEM's designers or work with the innovative boutique engineering firms. EMS firms also struggle with supply chain pressures for cost reduction and the application of the automotive supply chain processes.

Traditionally, Electronics Manufacturing Services (EMS) firms have been innovative on the production floor, introducing additive manufacturing and robotics but they have not known how to help the OEM's designers or work with the innovative boutique engineering firms. EMS firms also struggle with supply chain pressures for cost reduction and the application of the automotive supply chain processes.

Benchmark, a New Breed of EMS

For more than 40 years, Benchmark has been a leading EMS provider across multiple markets, exploring emerging technology in order to bring our customers the latest innovations and now coupled with significant investments in design and test support.

This allows Benchmark to provide leading edge technology solutions, the ability to scale to a global network of manufacturing facilities and the structure to handle the high mix low volume needs of aerospace and defense.

Our engineers work in production environments that use additive, liquid-cooled electronics, microelectronics and conventional board, assembly and box build with prototype lines available to help all the way through to production. Benchmark’s network of preferred suppliers reach beyond A&D providing additional buying power and availability.

Our goal is to reduce the development cycle by 1-2 years on average and provide an estimated IR&D savings of $20 - $100M.

Our goal is to reduce the development cycle by 1-2 years on average and provide an estimated IR&D savings of $20 - $100M.

This shift will provide significant growth for our OEM customers, by providing access to new and emerging technologies while at the same time addressing any issues early in the design process so that each stage of development and production is focused on increasing quality, reducing risk and accelerating the time to market.

Download a PDF of this article.

Some examples of our work include:

|

|

|

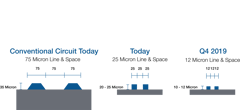

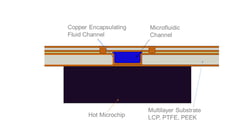

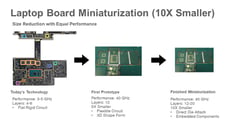

| Substrate board to system design for high speed and RF circuit fsor complex RF integrated solutions and custom RF. | Thermal circuit boards and board miniaturization. | Microfluidic in-board thermal management system. |

|

|

|

| Electronic miniaturization utilizing high performance materials (Liquid Crystal Polymer). | Design and testing of communication and RF products up to 110 GHz. | Mixed SMT and micro-e hybrid technologies with customer die packaging. |