Welcome to our blog series on Benchmark’s Centers of Excellence. Our Centers of Excellence represent locations within our worldwide network that have critical skills, knowledge, resources, training, and certifications surrounding a critical technology area or technical competency. In this series, we will explore our global facilities that comprise our Centers of Excellence and will highlight what makes them particularly suited to be given this prestigious title in a certain area of expertise. In our second article within our Centers of Excellence series, we head back to our facility in Almelo, the Netherlands to discuss the Electromechanical Center of Excellence we have established here.

Benchmark Center of Excellence for Electromechanical Systems

The engineering and manufacturing teams in Benchmark Almelo work on some of the most complex technologies across highly regulated industries such as avionics, complex industrials, medical, and semiconductor capital equipment. One of the key components in many of today’s applications within these industries is electromechanical and micro-electromechanical systems (MEMS).

MEMS is an incredibly powerful yet challenging and complex technology to work with. However, it is making a significant impact on the way products are developed and the capabilities it enables, so many organizations are investing in it. The process combines silicon-based microelectronics with micromachining technology. When integrated into a device, it enables the ability to sense, control, actuate on a micro-scale, and generate effects on a macro-scale.

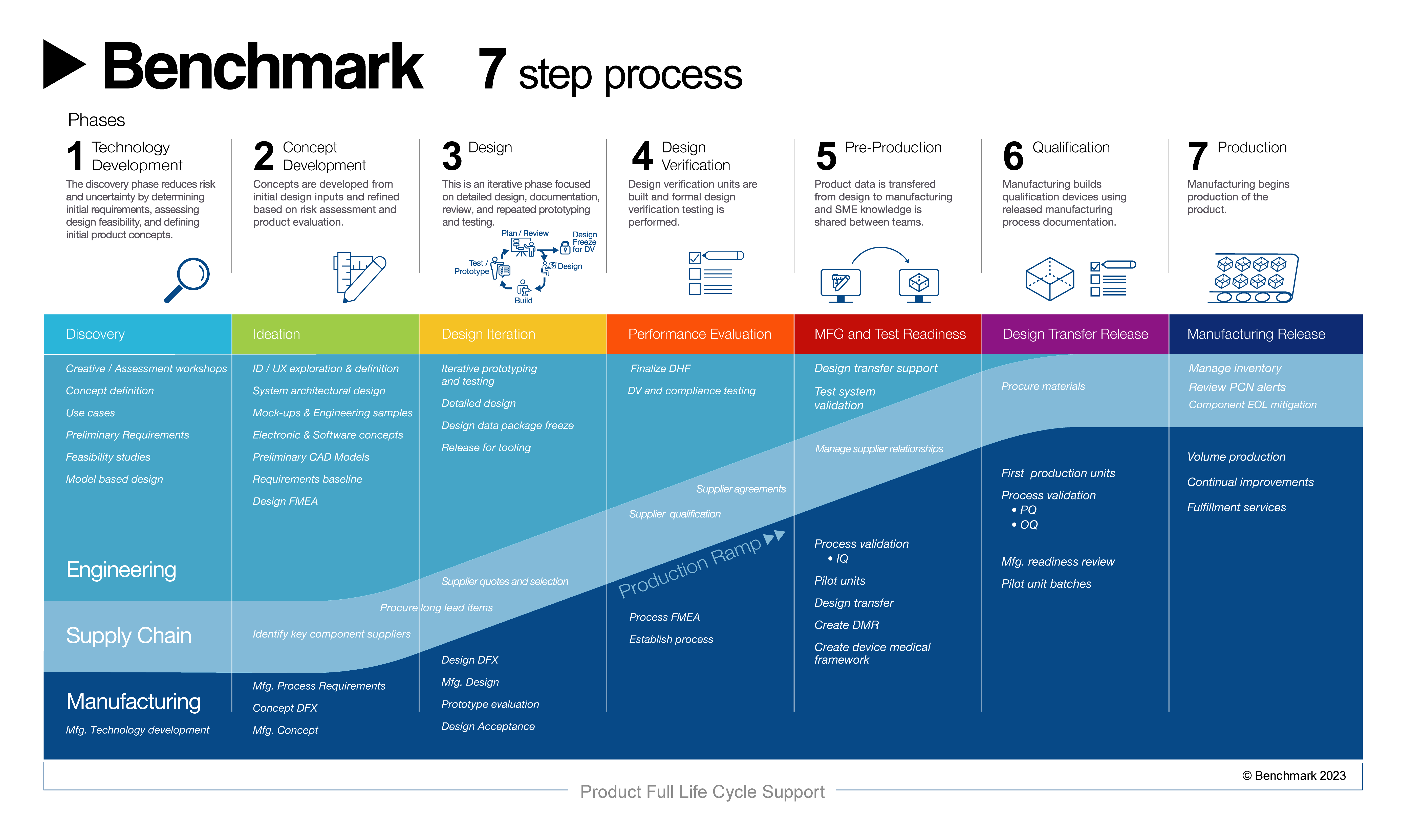

Here, at Benchmark Almelo, we have developed a proven track record serving advanced technology companies in motion control, power management, test and measurement, medical automated diagnostics, and wafer processing applications. We manufacture complex products for high reliability applications. Our Center of Excellence in electromechanical systems is made up of experienced personnel from our European design engineering group, manufacturing group, and supply chain strategists to deliver superior, integrated product realization. The team is experienced in executing complex and innovative projects from the initial concept phase through to development, new product introduction (NPI), manufacturing, fulfillment, and after-market sustaining services.

Some of the examples of the Electromechanical Systems and MEMS applications to which we have lent our expertise include:

-

High-Tech Mechatronics Modules and Systems, including actuator control boards, motor drives, and power amplifier controllers

-

Smart Sensors and Measurement Modules, including accelerometers for motion control and emergency brake systems, nanometer stage position systems, and ruggedized handheld measurement devices

-

Machine Conditioning, including flow and temperature control systems, fluidics systems, and vacuum systems

-

Complex Racks and Cabinets, including advanced control racks for controlling robots and non-standard computing racks

-

Electrification Systems, including robust power meters, analyzers, quality meters, smart power systems, and smart relays

Collaborative Work with Abionic

Demonstrating a real-world example of our excellence in electromechanical systems can be seen through our collaborative work with Abionic to help to develop an in-vitro diagnostic device. This project combined our expertise in electromechanical systems along with our other center of excellence capability here in Almelo, fluid management.

Abionic had developed a prototype for a novel nanofluidic system that provides on-the-spot biomarker measurement at the point of care and needed Benchmark’s help to take their device to market. To meet clinical requirements and disrupt the market, Abionic needed to reduce sample processing time, increase accuracy, and improve the overall quality and usability while keeping costs low. In addition to the core immunoassay technology of the platform, the final device had to be able to precisely manipulate the nanofluidic cartridge—a single-use element exchanged in every test—to align it with the onboard optical reader. To achieve this electromechanical challenge, Abionic relied on Benchmark Almelo to design a precise, three-dimensional positioning system using our design for manufacturing (DFM) expertise to bring the final device design together into a buildable product.

By utilizing a joint design approach, Abionic and Benchmark Almelo were able to successfully launch the abioSCOPE® into production. We applied our wide range of capabilities, specifically in electromechanical design and engineering, to help Abionic optimize the three-axis precision positioning of the nanofluidic cartridge contained within the abioSCOPE® and improve the fluorescence detection system. The team accomplished this through high-precision mechanics, an inventive driving solution, and dedicated control software which were all critical to ensure the reproducibility of the positioning process.

Collaborative Work with Fluke

In another example, we took on a unique project in the complex industrials sector with Fluke. Fluke was developing an acoustic imager designed to detect leaks in an industrial setting (the ii900 Sonic Industrial Acoustic Imager). The final product needed to be manufacturable at scale, so we had to take on an aggressive timeline to help Fluke become first to market with this innovative design. To solve manufacturability, we worked with Fluke on a creative configuration of components and data transfer sequences. This is the area in which we proved our unique capabilities in electromechanical systems. The solution utilized a camera interface (like the ones used on a smartphone) to create a pipeline to transfer video and audio data to the platform in a high bandwidth information stream of 30 Mbps.

By applying this solution and ruggedizing the device for an industrial environment, we were able to adhere to the project’s aggressive timeline, satisfying Fluke’s goal of being first to market with a high-quality sonic industrial acoustic imager that could be manufactured at scale. Due to our efforts, Fortive, Fluke’s parent company, presented Benchmark with the 2019 Gold Fortive Innovation Award for the ii900’s innovative design and functionality. The Fortive Innovation Awards are given to groups and products that accelerate progress through advancing essential technology, and Gold is the highest honor one can receive.

Due to our efforts, Fortive, Fluke’s parent company, presented Benchmark with the 2019 Gold Fortive Innovation Award for the ii900’s innovative design and functionality.

Electromechanical Systems and MEMS are not new technology but their applications are becoming more innovative and more complex. Benchmark Almelo has invested critical resources and hired the best of the best in terms of talent to meet the growing need for product realization services incorporating these technologies. We have the knowledge as well as the experience necessary to take our customers’ products to market quickly all while meeting their unique challenges and cost expectations. To learn more about Benchmark Almelo and our Electromechanical Center of Excellence, visit our page on Electromechanical Systems.