Advances in Technology for Millimeter Wave Antennas

With the advancement of modern manufacturing and fabrication technology, millimeter wave (mmWave) processes are becoming more commercially viable. Millimeter wave antenna arrays are emerging as a promising candidate for 5G systems. In addition, the high data rate of millimeter wave technology is becoming attractive for the technical attainment of long-promised value for the Internet of Things. Due to high data rate and small size of directive antennas at this range, radio-frequency identifiers (RFID) are also moving towards millimeter wave identifiers (MMID).

Substrate Choice and Fabrication Failures

Issues like path loss, rain absorption, conduction losses in metals, substrate losses and changes in substrate properties are well-known contributors to losses. There are challenges in choosing an appropriate substrate and challenges in its fabrication, but overcoming these challenges can be key to successfully reducing loss.

One very important variable to consider when selecting a substrate is the substrate’s dissipation loss. Though conductor losses are dominant at low frequencies, at frequencies above 10GHz, dielectric loss becomes the dominating factor contributing to the overall loss in a board. A substrate with a low loss tangent becomes very desirable at mmWave frequencies.

The moisture absorption in dielectric materials becomes a driving factor in mmWave ranges. The water molecules undergo a dielectric relaxation effect at 10 - 100 GHz, causing the dielectric constant to drop from 80 at a few GHz to about 5, and the water experiences a steep increase in the loss tangent. A material with a high water absorption rate increases losses in the antennas and the water absorption affects antenna gain directly. In addition, changes in dielectric constant (Dk) with frequency alter the resonant frequency of antennas at mmWave, making the antenna performance unreliable.

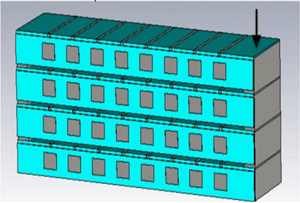

A multi-layered structure becomes necessary for an antenna to operate in multiple bands and polarizations. A reliable multi-layering process can guarantee an efficient use of a substrate in these antennas.

A multi-layered structure becomes necessary for an antenna to operate in multiple bands and polarizations. A reliable multi-layering process can guarantee an efficient use of a substrate in these antennas.

Flexible antennas are also valued in 5G architecture, anticipating applications in airborne, vehicular and body-area networks, which would facilitate a compact, robust and reliable integration in wireless technology.

These stringent substrate requirements rule out several commercial substrates at mmWave, but material science and manufacturing advances are opening doors to new solutions.

New Materials Offering a Path Forward

Recently, liquid crystal polymer (LCP) (Dk=3, Df=0.0016) has gained attention as a mmWave substrate solution. Characteristics like low coefficient of thermal expansion, flexibility, low water absorption, and low dissipation loss make LCP a promising candidate for a mmWave antenna substrate.  The low water absorption gives stability to LCP in a wide frequency range, which makes it a great choice of substrate for broadband antenna applications. The flexibility of LCP allows compact and conformal structures to be easier to construct and more reliable.

The low water absorption gives stability to LCP in a wide frequency range, which makes it a great choice of substrate for broadband antenna applications. The flexibility of LCP allows compact and conformal structures to be easier to construct and more reliable.

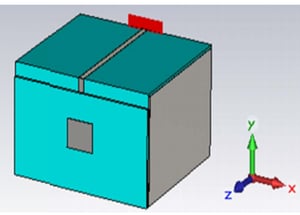

The conceptual drawing here shows one of these wrapping techniques, where an aperture coupled patch antenna array has its feed network on LCP wrapped on a metal block. This technique enables the placement of a transceiver to be on a substrate plane perpendicular to the antenna plane. This in turn gives freedom to choose the depth of the transceiver substrate independent from the antenna constraints for scanned arrays.

Precise and Efficient Multi-layering in Fabrication Technology is Key

Fabrication precision in mmWave is a concern since at this range of frequency any small changes in copper traces or vias during fabrication could directly affect the conductive, as well as radiative, performance of an antenna. Signal integrity at mmWave can be ensured by utilizing the latest developments in LCP fabrication technologies, such as the ability to attain 1 mil (25 micron) lines and spaces and high layer count, multi-layer boards.

An efficient multi-layering process would have lower stress and perfect alignment of layers. This can be attained by choosing a bonding material judiciously. Successful multi-layering opens doors for multiple functioning of antennas, a key requirement for 5G wireless communication.

Advancing our Future in 5G

Recent fabrication technology advances are making singular or arrays of antenna systems possible in mmWave. The advancements in precision manufacturing and miniaturization are advancing the current technology towards a future horizon of high-speed systems.

At Benchmark, we are experts in RF design utilizing LCP. At our RF and High-Speed Design Center of Innovation in Phoenix, AZ, we offer design services, mixed microelectronic assembly, complex product assembly, and test, all in one location. We design LCP circuits for the needs of the telecommunications, computing, industrial, and defense markets.

Want to talk to Benchmark engineers about using LCP and other advanced substrates to solve your antenna design challenges? Contact us.