Introduction

The race among cellular carriers (and countries) to be the first to deploy functioning mmWave 5G is driving demand for innovative and flexible network infrastructure like never before, opening the market for small-to-mid-sized organizations looking to fill unmet technological needs.

One key piece of hardware many of these companies are developing is antennas used to provide signals to millions of users. While these companies possess a wealth of expertise in addressing the technical challenges of developing a powerful cell phone signal, they may not have the depth of engineering necessary to tackle critical design issues such as thermal management and design optimization for manufacturability.

Benchmark partnered with a telecommunications infrastructure company on an antenna design to meet the network’s needs.

The Challenge

Our customer’s initial innovative, compact antenna design faced thermal management and manufacturability challenges common in newer wireless infrastructure designs that aim to reduce the overall product footprint. The customer engaged Benchmark for a Design for Excellence (DFX) process to address thermal issues and identify ways to reduce the cost to build the product. DFX is a method for creating better quality products at the concept design phase by balancing functionality, cost, manufacturability, and ability to test. This holistic methodology can reduce production times and costs while improving product performance.

The antenna prototype achieved signal performance requirements. Goals for the DFX initiative included meeting the requirements for operation outdoors on a cellular tower, which meant dealing not only with the heat generated by the device but also weather that could exceed 120 degrees with direct sunlight. Additionally, the customer wanted to look for ways to simplify the design to reduce the cost of the bill of materials (BOM), eliminate potential points of failure, and simplify the manufacturing process.

The Solution

Benchmark took on the task of developing a fanless thermal management solution to manage the internal heat while addressing the outdoor operation requirements. They developed multiple potential designs for the unit, ultimately selecting one that utilized a low-resistance thermal path to allow the antenna to maintain high-quality working conditions despite high temperatures. The design needed to allow heat to travel through the unit, meaning that conductive parts had to be separated without air gaps.

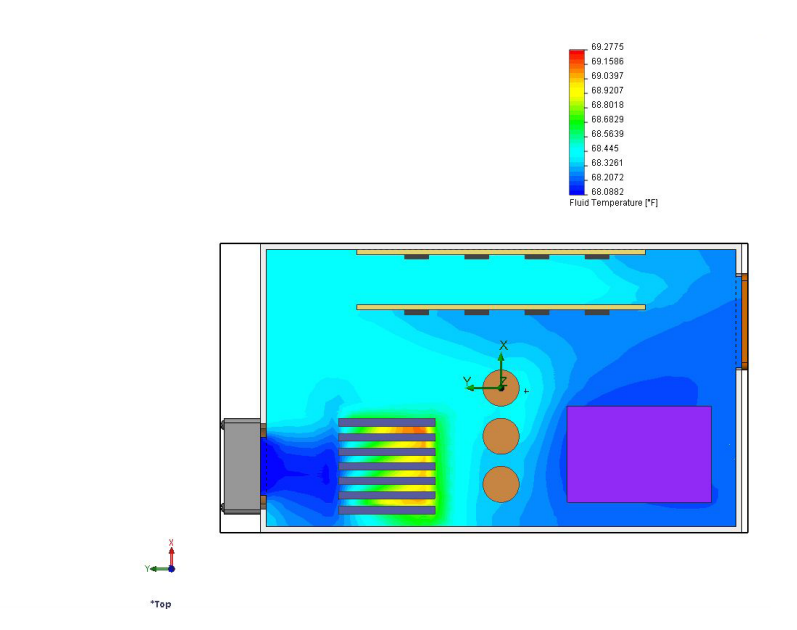

Figure 1. Solidworks CFD image showing an electrical enclosure with a finned heat sink on a processor and two circuit boards.

Figure 1. Solidworks CFD image showing an electrical enclosure with a finned heat sink on a processor and two circuit boards.

The Benchmark engineering team leveraged simulation and design software SOLIDWORKS® (Fig. 1) and CFD Module (an add-on product to the COMSOL Multiphysics® simulation platform) to evaluate numerous solutions quickly. The approach included designing hundreds of models that would go through the simulation process to determine how the heat would flow from the source to the vent heat exchanger and leave the unit. Ultimately, this allowed Benchmark to identify the design that would provide the optimal path to protect the internal components from heat and radiation damage, giving the customer their best option for thermal management.

Other thermal management design features were carried over from the prototype design and proved to be key manufacturability challenges, so Benchmark sought to provide better options for volume production. The original heat sink design included a backplate with many fins riveted to it. Benchmark simulated a hundred extruded designs with a wide variety of rivet options to create a single part that stood vertically so that air could flow from bottom to top. Not only did this simplify manufacturing, but it reduced BOM costs and increased the possibility for successful operations in the field.

The Results

Disputing markets required getting to market quickly while meeting product performance and cost goals—a mammoth task given finite staffing resources. For this company, focusing on signal and performance while choosing Benchmark for the thermal, manufacturability, and cost was a strategy for success.

This is the benefit of working with a trusted partner. From precision engineering to supply chain management, Benchmark provides the support that allows companies to focus on what they do best.

As the battle to win a place on the network of the future continues, Benchmark is ready to help address design and manufacturing challenges for network infrastructure equipment for any operating conditions. Benchmark solves complex challenges and delivers products on schedule with vast expertise across the RF spectrum.

About Benchmark

Benchmark provides comprehensive solutions across the entire product lifecycle, leading through its innovative technology and engineering design services, leveraging its optimized global supply chain and delivering world-class manufacturing services. The industries we serve include commercial aerospace, defense, advanced computing, next-generation telecommunications, complex industrials, medical, and semiconductor capital equipment.