Millimeter Wave Antennas are the Future of 5G

With the advancement of modern manufacturing and fabrication technology, millimeter wave (mmWave) processes are becoming more commercially viable and gaining industry attention. Millimeter wave (also called millimeter band) is the band of spectrum between 30 gigahertz (Ghz) and 300 Ghz. Researchers are currently testing 5G wireless broadband technology on the millimeter wave spectrum.

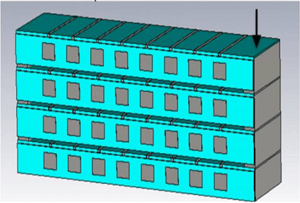

Antenna “arrays” are a set of multiple connected antennas which work together as one single  antenna. Millimeter wave antenna arrays are emerging as a promising candidate in 5G systems. The high transfer data rate of millimeter wave is becoming attractive for the technical attainment of 5G speed and practical fulfillment of the promises of the Internet of Things (IoT) revolution. The interaction between data collected from IoT sensors and information from cloud processing relies on the ability to transfer data quickly to make decisions in real time. Figure 1: mmWave Antenna Array

antenna. Millimeter wave antenna arrays are emerging as a promising candidate in 5G systems. The high transfer data rate of millimeter wave is becoming attractive for the technical attainment of 5G speed and practical fulfillment of the promises of the Internet of Things (IoT) revolution. The interaction between data collected from IoT sensors and information from cloud processing relies on the ability to transfer data quickly to make decisions in real time. Figure 1: mmWave Antenna Array

Challenges When Selecting a Substrate Board Material for mmWave

Everyone would like the speed and capability mmWave promises, but there are substrate fabrication challenges to building practical mmWave antenna systems today. Stringent substrate circuit board requirements of mmWave technology rule out the use of several commercial dielectrics like FR4 for the choice of board material. Issues like path loss, water absorption from rain, conduction losses in metals, substrate losses and changes in substrate properties are a few well-known contributors to signal loss. Too much loss will prevent antenna functioning at the mmWave frequencies engineers are trying to obtain in their designs.

I will highlight some of the substrate selection challenges below.

Dissipation Loss

One very important variable to consider when selecting a  substrate is the substrate’s dissipation loss. Though conductor losses are dominant at low frequencies, at frequencies above 10 GHz, dielectric loss becomes the dominating factor contributing to the overall loss in a board. Thus, a substrate with a low loss tangent becomes very desirable at mmWave frequencies.

substrate is the substrate’s dissipation loss. Though conductor losses are dominant at low frequencies, at frequencies above 10 GHz, dielectric loss becomes the dominating factor contributing to the overall loss in a board. Thus, a substrate with a low loss tangent becomes very desirable at mmWave frequencies.

Moisture Absorption

The moisture absorption in dielectric materials also becomes a driving factor in mmWave ranges. Water molecules undergo a dielectric relaxation effect at 10 - 100 GHz, causing water’s dielectric constant to drop from 80 at a few GHz to about 5, and water also experiences a steep increase in its loss tangent. It then makes sense that utilizing a board material with a high water absorption rate will increase loss in the antenna itself, and the water absorption will affect antenna gain directly. In addition, changes in water’s dielectric constant (Dk) with frequency will alter the resonant frequency of antennas at mmWave, making antenna performance unreliable.

Multi-layered Processes needed for Compactness

A multi-layered structure becomes necessary for an antenna to operate in multiple bands and polarizations. Current multi-layer fabrication processes are limited in industry today. A reliable multi-layering process would guarantee an efficient use of a substrate in mmWave antennas. Compact antennas are also valued in 5G architecture, anticipating applications in airborne, vehicular and body-area networks, which would facilitate a robust and reliable integration into wireless technology.

New mmWave 5G Fabrication and Substrate Options are Here

I have touched on several challenges designers face when picking a substrate material for building mmWave antennas above, but there is good news. Reliable new options that negate mmWave fabrication and board selection challenges are available today. Benchmark designs circuits using high-performance, low-loss substrate materials to rapidly advance current technology towards a future horizon of high-speed mmWave systems. Benchmark’s engineers are utilizing recent material and fabrication technology breakthroughs to make singular antennas and arrays of mmWave antenna system design a practical choice.